What Is Supply Chain Planning? Key Business Benefits Explained

Supply chain planning is the corporate activity that focuses on allocating resources as well as time and place for the production and delivery of goods and services. It is used to achieve operational efficiencies, manage/minimize risks, and contain costs in many sectors. Supply chain planning improves decision-making, customer satisfaction, and the ability of a business to respond to change. This explains how they can incorporate quick supply chain software and adopt various cost-cutting measures in an organization. Risk management is especially included under supply chain management since the chain still has to stay operational even in the most adverse conditions. Learn how supply chain planning breathes life into an organization and how it creates sustainability and profitability.

Ready to transform your business with smarter supply chain strategies? Subscribe now and let’s dive in!

What Is Supply Chain Planning?

Supply chain planning is an operational management process of organizing a supply chain based on forecasting and planning the actual customer demand and planning the production process and delivery of products to customers. It makes expenses according to resources without compromising costs and it maintains low risks for the usage of resources.

Process Overview:

- Understanding Customer Demand – Forecasting future needs through historical data and market trends.

- Inventory Management & Production Planning – Balancing stock levels to avoid overstocking or shortages.

- Distribution & Delivery Optimization – Ensuring timely, cost-effective product delivery.

Types of Supply Chain Planning:

- Demand Planning: Predicting future customer needs.

- Production Planning: Scheduling manufacturing processes.

- Supply Planning: Managing resources and materials.

- Sales & Operations Planning (S&OP): Aligning sales, production, and logistics.

Importance of Supply Chain Planning: By integrating risk management, businesses achieve cost reduction and improve efficiency using modern supply chain software solutions.

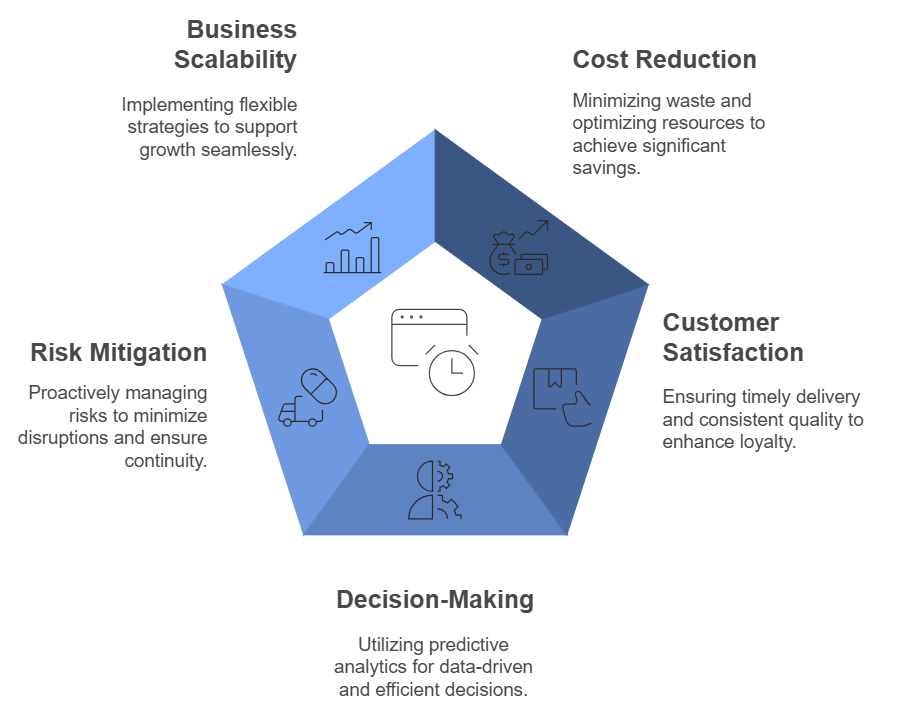

Why Is Supply Chain Planning Important?

1. Reducing Operational Costs: Effective supply chain planning minimizes waste and optimizes resources, leading to significant cost savings.

2. Improving Customer Satisfaction: Timely delivery and consistent quality ensure a better customer experience and loyalty.

3. Enhancing Decision-Making: Predictive analytics empower data-driven decisions, improving supply chain efficiency.

4. Mitigating Risks and Disruptions: Proactive risk management minimizes disruptions, ensuring business continuity.

5. Scaling Business Operations Efficiently: Flexible supply chain strategies support seamless scalability during growth phases.

Pro Tip: Leverage supply chain software for better cost-reduction strategies and efficient risk management.

Supply chain management is important for driving operational excellence while maximizing customer satisfaction and long-term profitability.

The Business Benefits of Supply Chain Planning

Supply chain planning delivers significant business benefits by optimizing operations, enhancing customer satisfaction, and reducing risks. By focusing on cost savings, businesses can minimize waste and streamline processes, as demonstrated by XYZ Company’s $X million savings through effective planning. Improved efficiency eliminates bottlenecks, increasing production speed with tools like supply chain automation. Risk management in supply chains is bolstered by AI and Machine Learning, helping predict disruptions and safeguard operations. Enhanced customer experiences arise from faster deliveries and better inventory control, fostering loyalty. Additionally, supply chain planning leverages data analytics to forecast demand and drive smarter decisions. Adopting advanced supply chain software ensures businesses achieve sustainable growth and maintain a competitive edge in today’s fast-evolving markets.

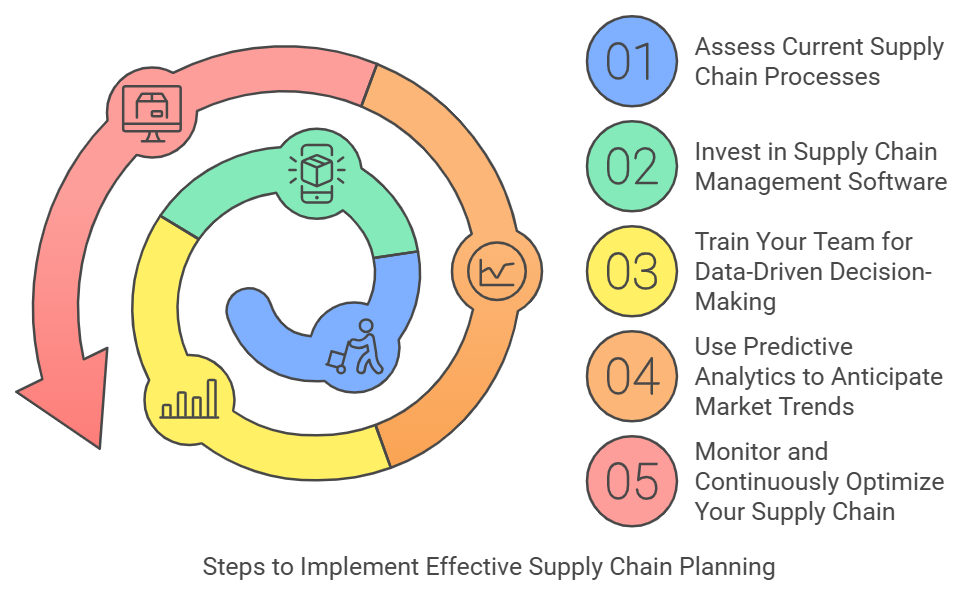

Steps to Implement Effective Supply Chain Planning

Step 1: Assess Current Supply Chain Processes

Evaluate your existing supply chain to identify inefficiencies and areas for improvement. This helps establish a clear baseline and set actionable goals.

Step 2: Invest in Supply Chain Management Software

Adopt advanced supply chain software to automate processes, improve visibility, and enhance data management, reducing errors and boosting efficiency.

Step 3: Train Your Team for Data-Driven Decision-Making

Provide training to help your team interpret data effectively. This ensures decisions are informed, improving risk management and operational agility.

Step 4: Use Predictive Analytics to Anticipate Market Trends

Leverage predictive analytics to forecast demand, mitigate risks, and adapt to market changes, ensuring smoother and cost-effective operations.

Step 5: Monitor and Continuously Optimize Your Supply Chain

Track performance metrics regularly to maintain efficiency. Use insights to refine strategies, explore cost reduction, and adapt to evolving business needs.

Supply Chain Planning Trends for 2024 and Beyond

The future of supply chain planning focuses on technology and sustainability. The importance of supply chain management is rising as businesses strive for efficiency and resilience in a dynamic market.

AI and machine learning improve the tools for better forecasts of demand and risks of supply chain management. One of the ownerships of IoT devices resulting from their integration is the constant stream of data in real-time that allows for quick response to disruptions.

Environmentalism is important, with corporations steering themselves in more environmentally friendly directions. And, secure ports safeguard data in integrated networks at the same time during sending and receiving information.

Optimum supply chain software includes features in abilities for sound decision-making and cost-cutting strategies leading to better operations. These trends put emphasis on the ways of how supply chain planning can help to develop more resilient supply chains in 2024 and further.

How to Get Started with Supply Chain Planning

Effective supply chain planning boosts operational efficiency. This consists of a self-evaluation of the needs of the business organization and determining the issue areas of concern. Supply chain management knowledge means that your strategy is properly aligned with organizational goals.

Ask professionals or turn to improved supply chain software to optimize risk management in supply chains and their processes. Begin with selected applications, like cost control measures, and expand as results rise.

The advantages that organizations are likely to accrue from supply chain planning involve; reduced costs, overall enhanced efficiency, and overall reduction in risks. A good plan reduces complications that may be the case when operating without one and keeps various businesses relevant particularly when delivering customer needs.

These steps lay the foundation for long-term resilience and success in today’s dynamic market.

In summary, Supply chain planning is a business activity aimed at promoting effective and efficient execution of the supply chain to address various challenges. Some of the advantages of supply chain planning include; Enhanced demand forecasts, decreased risks, and better methods of expense cutting. They themselves point to the fact that its importance resides in the fact that it helps businesses quickly respond to shifts in the market and satisfy customers.

Looking for more strategies to optimize your supply chain and stay ahead of the competition? Check out our latest articles for expert insights, actionable tips, and industry trends that will transform your business operations:

- https://www.digitalexperience.live/master-analytics-leadership-blueprint-success

- https://www.digitalexperience.live/optimize-your-customer-success-program-growth

- https://www.digitalexperience.live/data-leaders-shape-generative-ai-strategies

FAQs:

1. What are the benefits of supply chain planning?

Supply chain planning reduces costs, improves efficiency, and enhances customer satisfaction. It also helps businesses forecast demand accurately, manage inventory better, and minimize risks, leading to increased profitability.

2. What is supply chain planning?

Supply chain planning is the process of forecasting demand, managing resources, and optimizing operations to ensure products are delivered efficiently. It involves demand planning, production scheduling, and logistics coordination to meet business goals.

3. How does supply chain benefit business?

Effective supply chain planning boosts profitability by reducing waste, lowering costs, and improving delivery times. It also strengthens customer relationships, enhances decision-making, and increases flexibility in handling market changes.

4. Which of these is a benefit of supply chain planning and execution?

Key benefits include cost savings, faster delivery, improved risk management, and enhanced customer satisfaction. It ensures a smooth flow of goods and resources, driving operational efficiency and business growth.